GLOBAL Optics offers high-resolution optical measurements for small shape and size details on challenging surfaces. It is ideal for non-contact measurement of geometric dimensions and form features on sensitive workpieces that cannot be touched, as well as those with particularly difficult surfaces. This system comes standard with a chromatic white light sensor. The chromatic white light sensor can be optimally aligned with the measured surface using an indexing probe head.

This feature provides excellent access to part characteristics from nearly any angle or direction. Additionally, Hexagon’s opto-mechanical sensor interface and automatic sensor changer rack facilitate the easy swapping of various sensors on the indexing probe head, enhancing the versatility of the CMM with multiple sensor options.

Features and Benefits

- Global Coordinate Measuring Machines (CMMs) are designed using advanced concepts that prioritize assurance and clarity. They aim for long-term stability, reduced measurement uncertainty, adaptability to challenging conditions, quick point capture, and an improved user experience by integrating high-quality components with state-of-the-art technologies.

- Manufacturers can maximize the benefits of these metrology solutions throughout their entire lifecycle.

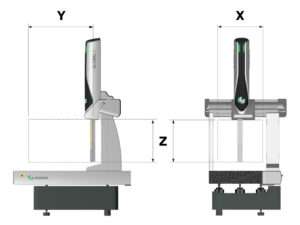

- The robust mechanical design features a strong granite foundation with an integrated dovetail guide, ensuring consistent accuracy across the measuring volume and long-term system stability.

- Additionally, the triangular crossbeam bridge design offers a superior stiffness-to-mass ratio compared to square or rectangular traverses, enabling maximum dynamics and high-speed measurements.

- All axes have preloaded air bearings.

Contactless, low-friction and low-wear axis motion ensures fast and repeatable positioning at all speeds and accelerations, resulting in low measuring uncertainties. - Belt drive system that requires less upkeep

Flat and V-ribbed belts ensure smooth and low-vibration axis motion. - Compensation for temperature

Reliable measurement findings are ensured by using temperature monitoring at the scales and on the workpiece to compensate for thermally generated measurement discrepancies in real-time. - Increased operating temperature range (option)

Measure your components more resistant to the effects of the environment. Without requiring an expensive climate chamber, the CMM can function closer to the manufacturing line thanks to its wider temperature operating range (15–30°C).

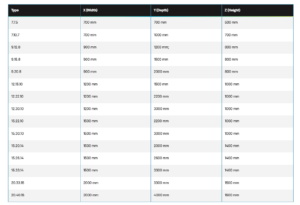

Measuring volume