Leitz Reference Precision provides exceptional high-speed scanning capabilities while maintaining excellent accuracy and precision. The model’s fixed scanning head ensures consistent and repeatable accuracy, even when using large stylus clusters and extra-long probe extensions. This feature allows users to perform high-accuracy scanning across a broader range of measuring tasks, including examining features deep within components. Additionally, a modular sensor and stylus changing rack enable users to select the best stylus options for each specific application.

Leitz Reference CMMs are designed with advanced concepts to inspire confidence and reliability. They incorporate high-quality components and cutting-edge technologies to ensure long-term stability, reduced measurement uncertainty, adaptability to challenging measuring conditions, quick capture of measurement points, and an enhanced user experience. Manufacturers can maximize the benefits of these metrology solutions throughout their entire lifecycle.

Features and Benefits

Robust Mechanical Design

Experience unmatched precision and long-term stability with a robust mechanical design anchored by a strong granite foundation and integrated dovetail guides, ensuring accuracy across the entire measuring volume.

Triangular Crossbeam Bridge

Enhance your operational efficiency with our triangular crossbeam bridge design, which offers an exceptional stiffness-to-mass ratio for superior dynamics and the capability for high-speed observations unmatched by traditional square or rectangular designs.

Preloaded Air Bearings on All Axes

Achieve low measurement uncertainties with our advanced preloaded air bearings, delivering contactless, low-friction, and low-wear motion. This ensures swift and repeatable placement at all speeds and accelerations, enhancing your productivity.

Low-Maintenance Belt Drive System

Our innovative belt drive system, featuring both flat and V-ribbed belts, guarantees smooth and low-vibration axis motion, significantly reducing maintenance needs while maximizing performance.

Advanced Temperature Compensation

Ensure reliable measurement results with our real-time temperature compensation system, which monitors temperatures at scales and workpieces, effectively addressing thermally induced discrepancies and maintaining accuracy in every condition.

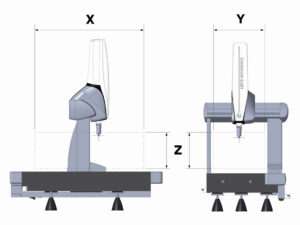

Measuring volume

-

Type X (Width) Y (Depth) Z (Height)* 5.4.3 500 mm 400 mm 300 mm ** 7.7.5 700 mm 700 mm 420 – 500 mm ** 10.7.6 1000 mm 700 mm 580 – 650 mm ** 12.9.7 1200 mm 900 mm 700 mm**

560 mm***15.9.7 1500 mm 900 mm 700 mm**

560 – 640 mm ***20.9.7 2000 mm 900 mm 700 mm**

560 – 640 mm ***15.12.9 1500 mm 1200 mm 940 mm**

800 mm***22.12.9 2200 mm 1200 mm 940 mm**

800 mm***30.12.9 3000 mm 1200 mm 940 mm**

800mm ***40.12.9 4000 mm 1200 mm 940 mm**

800mm **** Values depend on selected sensor configuration

** Values for machines equipped without SENMATION

*** Values for machines equipped with SENMATION -