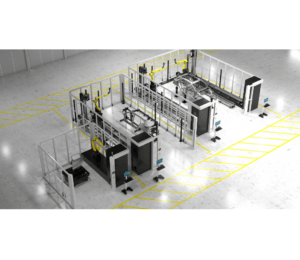

The PRESTO System is an advanced modular suite of automated robotic inspection cells that is revolutionizing 3D measurement in the aerospace and automotive industries. This technology is designed to be future-proof, setting a new standard for automated quality inspection that is scalable, adaptable, and seamlessly integrated.

With the PRESTO System, robust robotic inspection can be developed, tested, and implemented within a matter of hours, requiring only one quality control specialist. Additionally, since the PRESTO System is compatible with various metrology software, employees of all skill levels can operate it without needing extensive retraining. For ongoing benefits, empower your team with Hexagon’s inclusive technology.

Adopt PRESTO to eliminate the need for additional spending on software retraining.

Adopt PRESTO to eliminate the need for additional spending on software retraining.

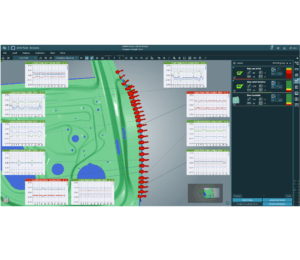

From the start, PRESTO seamlessly integrates with industry-leading metrology software programs such as PC-DMIS, Inspire, and PolyWorks. The invaluable data assets provided by the PRESTO System can help your company achieve its full potential.

Explore the various software options offered by Hexagon, which can facilitate quicker decision-making and prompt corrective actions. Since PRESTO Systems are modular, you can consider upgrading to features that may not have been feasible when you initially purchased them.

One of the ways Hexagon promotes ethical and sustainable production is through the inherent scalability of its solutions.